Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Snap lock roofing sheet is mostly used on warehouses, factories, and other construction buildings. It is easy to install, there are no bolts and nuts on the roofing sheet surface, looks beautiful, and prevents rust from nut holes. This snap lock standing seam machine we made for a Belarusian client, let’s introduce the machine details.

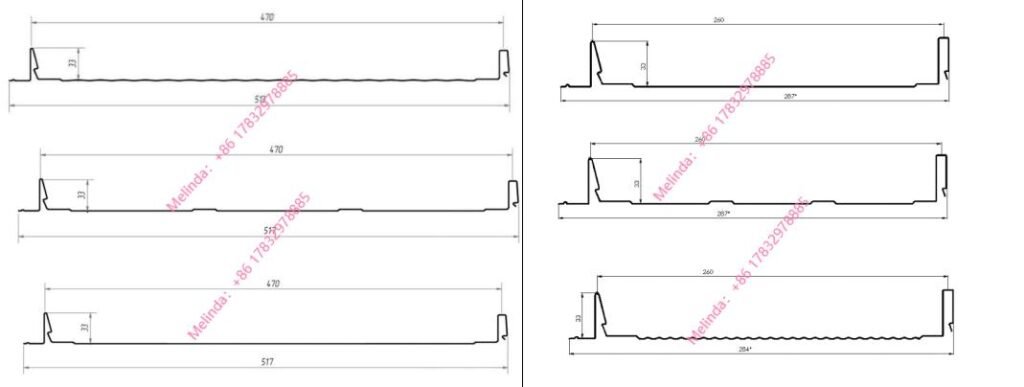

This is an automatically adjustable width snap lock roofing machine, one machine produces multiple sizes, with different ribs. Below are the profile drawings:

Wall cladding snap lock machine main parameters:

2. Snap lock main forming machine

3. Electric system

This standing seam forming machine can produce multiple sizes, but every size with different ribs. How to produce the ribs?

There are 3 rolling stations at the end of the forming machine, used to press the ribs. Clients can choose which rolling station to use, depending on the order request. The gap between the up and down rollers is adjustable through the manual wheel.

If you need to buy a snap lock standing seam machine like this, contact us freely!