Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Metal embossing machine, also named stucco metal embossing machine, checkered plate making machine. It is a specialized industrial equipment designed to create raised or indented patterns (typically diamond or other geometric shapes) on metal sheets, enhancing their anti-slip properties and aesthetic appeal.

Main technical parameters

| Patterns | willow leaf, CNC engraving |

| Depth of pattern | 1-2.5mm, adjustable |

| Embossing rollers | ø500*1600mm |

| Rollers material | 42CrMo , solid forged alloy steel |

| Rollers Hardness | HRC55-58 |

| Roller surface | chromed |

| Drive mode | Speed regulation by frequency conversion |

| Machine structure | Steel plate welded |

| Embossed way | Double side pressing, concave and convex pressing |

| The way of adjust pressure | By reducer motor |

| The clearance of the two rollers | adjustable |

| Cycloid reducer | XWD106-507 |

| Frequency motor power | 15kw |

| Brand of frequency | Delta brand |

| Speed | 0-4m/min |

Our advantage of embossing machine:

How to adjust the gap between two rollers is the most asked questions from clients. It is easy to operate. There are 2 types, one type through manual wheel to adjust the gap, one type through servo motor adjust the gap.

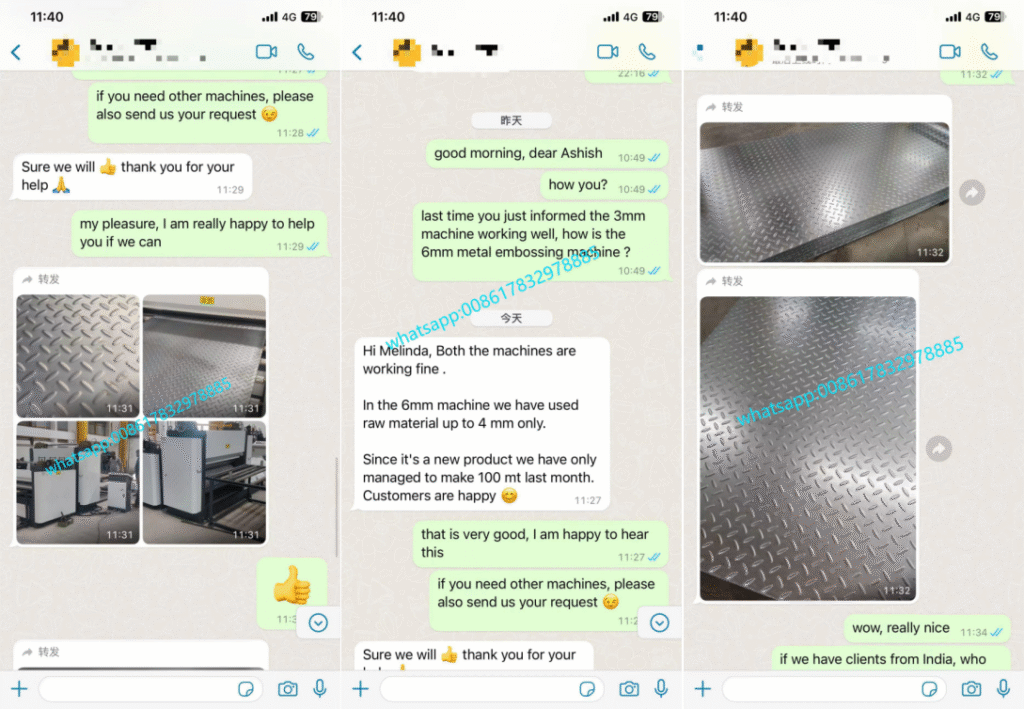

Real comments from Clients

Contact us freely!!!