Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

The gypsum Beacon Rail Channel almost certainly refers to the gypsum plastering track system (also known as plaster supporting bar). These are temporary tracks or rails installed on the wall, serving as a guiding tool for achieving a perfectly flat and level plastering surface.

The main component of the supporting bar roll forming machine

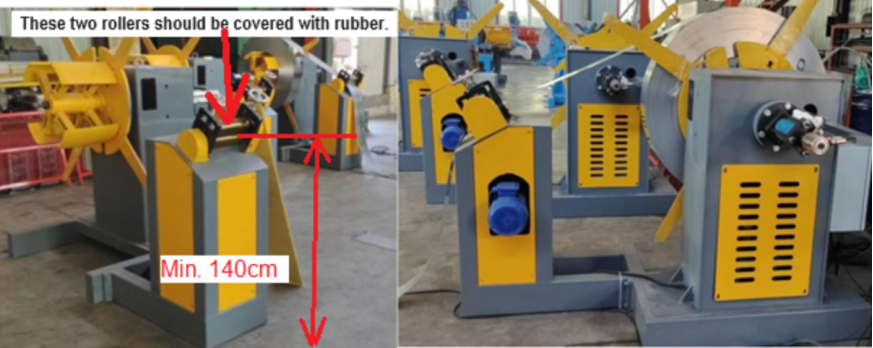

1. Hydraulic uncoiler with drag rollers

Work type: hydraulic type

Usage: to support the coil and make the uncoiling

Loading capacity: 3 tons

Inner diameter:470-530mm

Coil width:200mm

Drag rollers will be covered with rubber

2. Fast speed press machine

Driven by servo motor: power 15KW

Servo feeder used to feed steel strip into a fast-speed press machine, controlled by an independent electric system

3. Supporting bar roll forming machine

11 rolling stations

Roller’s material is Cr12 steel, heat-treated. HRC58-62

Shaft material is C45 steel, diameter 50mm

The machine structure is a cast-iron structure

The machine transmission is by chains

4. Fly cutting

Fly cutting, when the support bar making machine does cutting, the machine continues cutting without pause, speeds up to 38m/min.

5. Semi-auto runout table

length 3m

Cangzhou Zhongtuo Roll Forming Machinery Co.,ltd.. is a professional manufacturer of large and

medium-sized machinery and equipment. We are a new high-tech enterprise, the master research

base of YANSHAN University, and have more than 20 patent certificates by 2024. Professional sales

team, experienced technical engineers, and skilled production mechanics are the greatest factors in our

success. Mr Cary Xu, the founder of the factory, is a professional sales engineer who has been engaged

in the design and manufacture of cold forming machines since 2006.

Our machines are exported to over 170 countries, achieving good fame. 60% orders come from repeat clients, due to our machine’s good quality and after-sales service.