Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

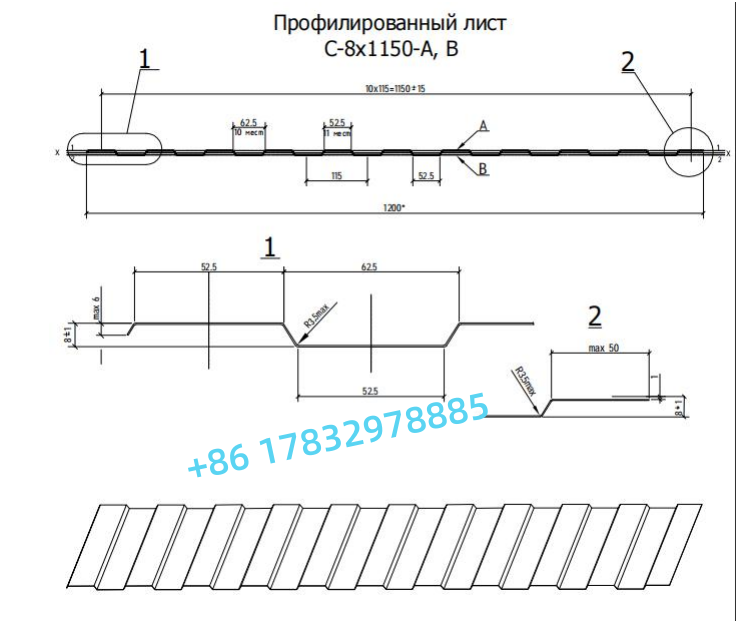

C8 C10 is a traditional and popular profile in the Russian market. The C8 C10 metal sheet could be used on roofing and wall cladding. The detailed profile drawing is shown below:

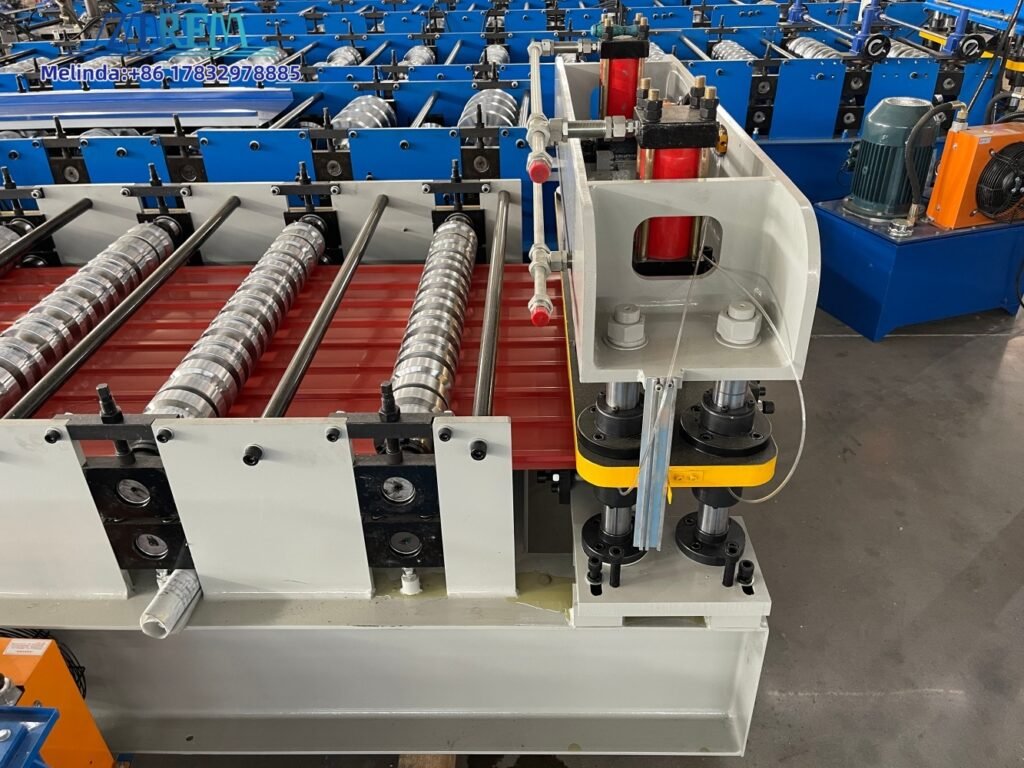

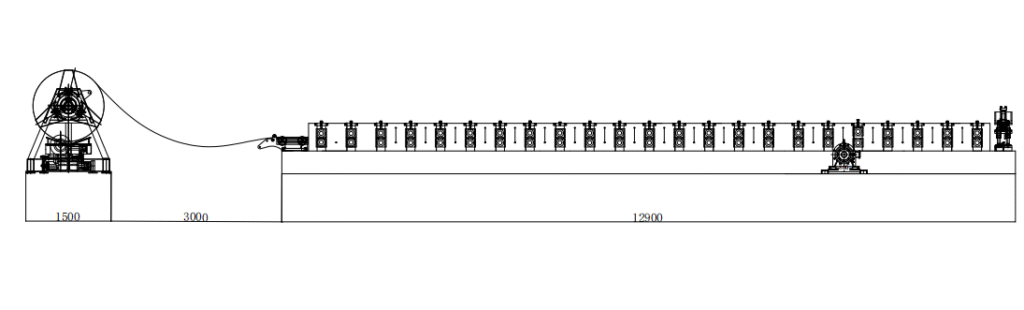

The C8 Iron sheet forming machine’s main components include 1 set of decoiler, 1 set of roll forming machine, 1 set of runout table, 1 set of PLC control cabinet, 1 set of runout table.

The main technical specification:

The advantage of the ZTRFM metal sheet roll forming machine is shown below:

2. The basic frame with diagonal bracing and cross bracing, which guarantees the machine’s basic frame is very stable. It will not get deformed during loading into the container, and after many years of use.

3. The shaft and rollers are connected by a key groove and keys. This ensures the shaft and rollers will not loosen after years of use. Adopt a double lock system, which ensures the shaft will not loosen; it is very stable when installed on the machine body.

4. There are oil lubrication systems, which are used to lubricate the columns. This can increase the cutter structure’s lifetime.