Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

What is a cable tray roll forming machine?

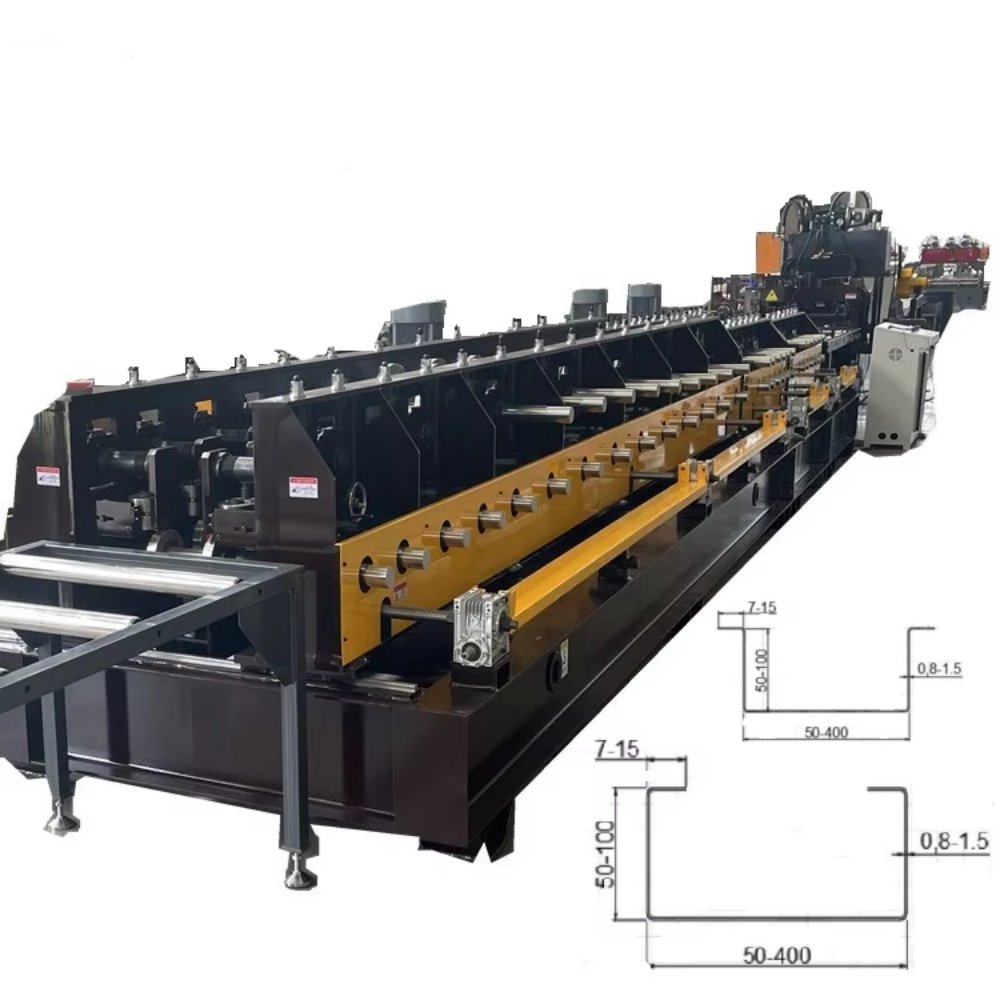

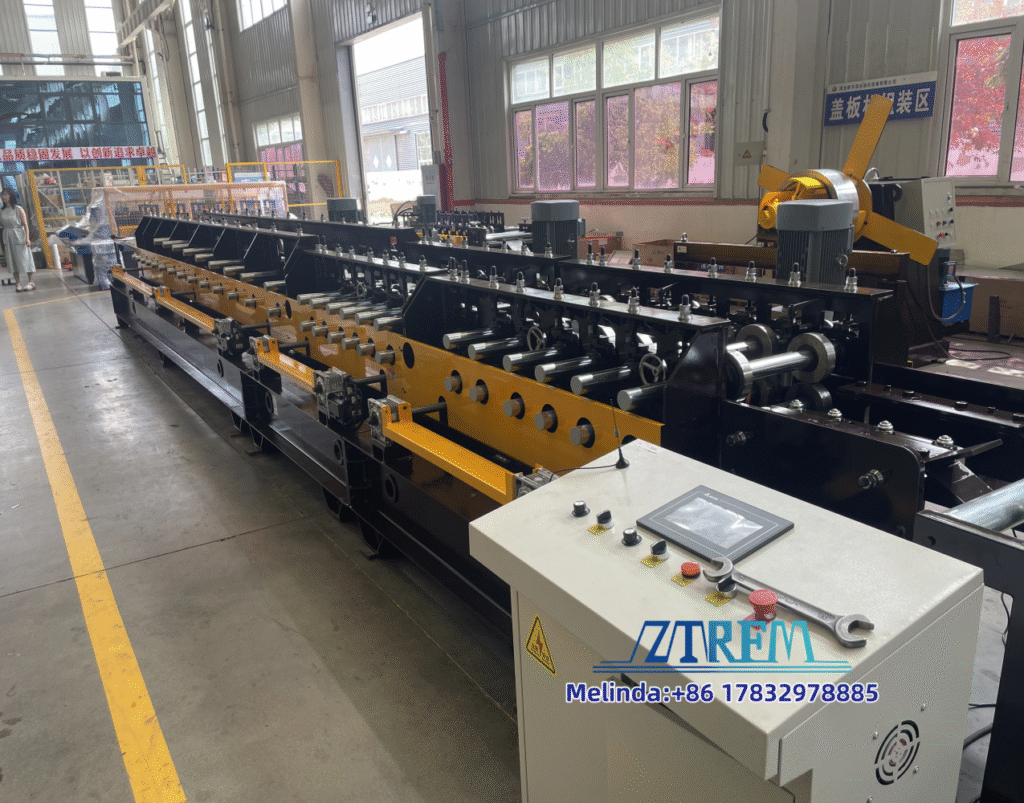

A cable tray roll former is specialized equipment used to produce cable tray profiles. The cable try forming machine takes flat steel strips and shapes them through a series of rollers. The video below is of a simple cable tray machine, which can produce 50-400.

The main component of the cable tray roll forming machine includes a hydraulic uncoiler, a leveler, a punching and pre-cutting machine, a fast speed transport table, a roll forming machine, and a runout table.

2. Leveler, punching, cutting machine

Levelling rollers: up 3 + down 4, total 7 levelling rollers

The hydraulic punching with one set of punching moulds, the mould material is SKD11(Cr12MoV).

The cutting blade material is Cr12MoV.

3. Fast speed transport table, it is used to transport the cut sheet to the roll forming machine.

4. The cable tray forming machine

rolling station: 26 rolling stations

The shaft material is high-quality C45 steel, and the shaft diameter is 65mm.

The roller material is Cr12 steel, through quenched treatment, HRC 58-62.

The main motor power: 5.5KW X3 sets

Changing size controlled by an electric motor, power 0.37KW x 2 sets

The advantage of this cable tray machine: