Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

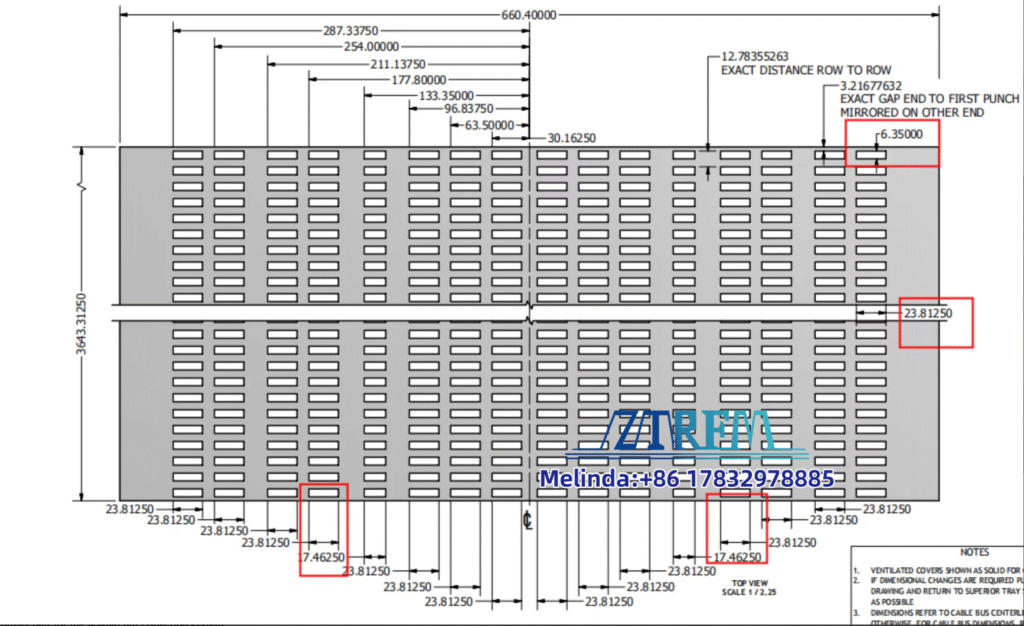

This is a perforated metal sheet cutting machine. It is different from a traditional coil cut to length line. As per the client’s request, we put a press machine in the middle of the leveling machine and cutting machine. The press mould is customized according to the client’s hole drawing. Below is the client’s drawing for your reference.

This is an automatic production line. The press mould and the servo feeder control the punching speed. The PLC controls the cutting length and cuts automatically. The main component of this perforated steel sheet cutting machine is as follows:

The coil cart is used to load the coil onto the decoiler and load the coil back from the decoiler. The coil cart moves forward and back, controlled by an electric motor. The panel goes up and down, controlled by a hydraulic motor.

2. Leveler

This leveler is used to make the steel flat. There are 2 sets of guiding rollers, up 3 + down 4 leveling rollers, for a total of 11 rollers. Leveling machine driven by an electric motor. The gap between the top and bottom rollers is adjusted by a manual or servo motor.

3. Press machine

The press machine is a Yangli brand, with one set of press moulds. The press mould material is SKD11.

4. Leveler

After the steel sheet goes through the press machine, it needs to undergo a second leveling.

5. Cutting machine

This part is used to cut the sheet to the desired length. The cutting blade has 4 sides. The blade material is SKD11.

6. Automatic stacker

This part is used to receive the sheet and to tidy the sheets. The length of the stacker could be customized according to the client’s request.

7. The perforated metal sheet coil cut to length machine run video for your reference

Contact us for more information please!