Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

The Cable Tray Roll Forming Machine (also known as a Cable Tray Rolling Forming Machine) is a core piece of equipment specifically designed for the continuous and mass production of cable trays. It adopts the cold bending roller rolling process, gradually rolling the metal sheet (steel, aluminum, stainless steel) into the desired cross-sectional shape at room temperature. One machine can produce multiple sizes, 100-600mm in width.

The main components of the cable tray rolling machine include the uncoiler, leveler, servo feeder, punching machine with punching mould, roll forming machine, cutting machine, and runout table.

Next, we learn the cable tray machine in detail:

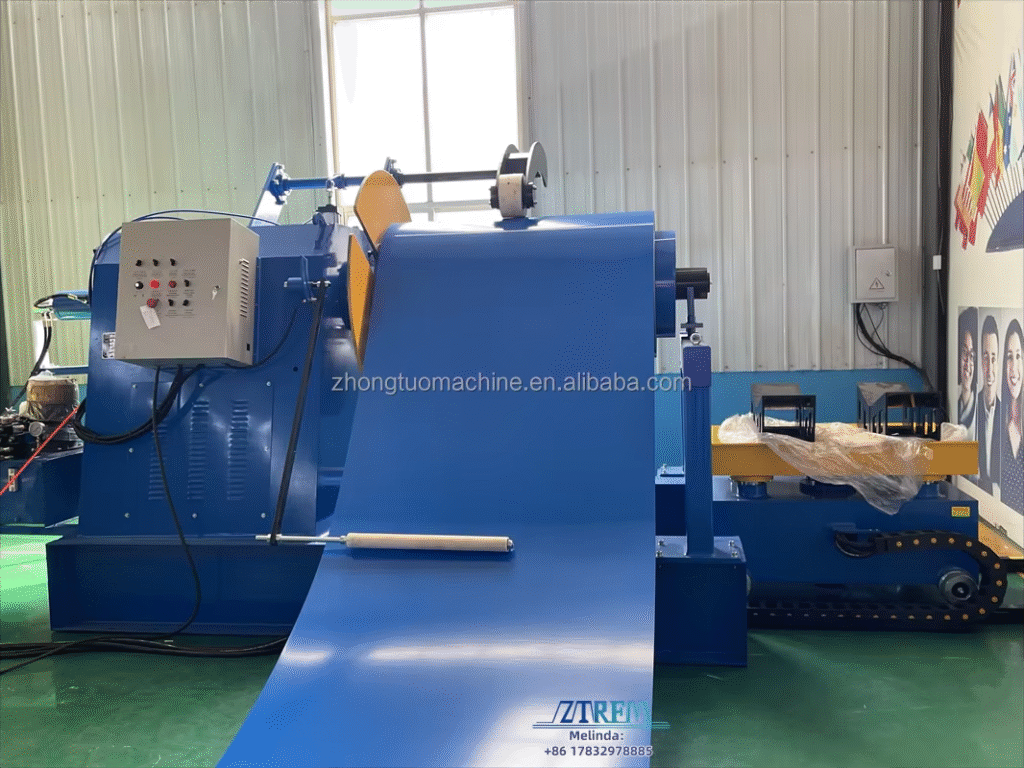

1. Hydraulic uncoiler

Dimension: 3400x1600x1800mm

Weight: around 2.9 tons

Hydraulic station: motor power 4kw

Main motor: power 5.5 kW

Expand way: slider expanding, 4 PCS supporting arm

Supporting coil spindle: made by a thick seamless steel pipe, fine lathe processing, diameter 203mm, thickness 55mm

Capacity: 10 tons

Decoiler with Pneumatic press arm

Decoiler with Pneumatic brake Advantage:

①The bearing spindle is made of high-strength, fatigue-resistant back wall seamless steel, which is processed by turning and has strong strength and heavy bearing.

② Decoiler adopts hydraulic control, convenient, fast, and stable

③ electrical control, high precision, good degree of automation, frequency converter control, the speed can be adjusted

2. Leveler

Leveling rollers: up 3 + down 4

pinch rollers: 2 sets

3. Servo feeder, punching machine, and punching moulds

Servo feeder model: NCF-800

Punching machine brand: YangLi brand

4. Cable tray roll forming machine

Rollers: Cr12, quenched, HRC 58-62

Shaft: diameter 60mm, cantilever type, material is high-quality No.45 steel, fine processing

Rolling station:26 rolling station

Machine structure: integral welded archway frame

Machine basic frame: 400H beam welded

Main motor power: 5.5KW x 3 sets

Width adjusting control by 2 sets of servo motors, power 1.5kw + 1.5kw

Transmission: by gear box

Speed: 8m/min

5. Runout table

If you need a good quality machine, contact us freely!